RFID and Beacon technologies may be in the headlines for retail nowadays, but they got their start in manufacturing. Radio Frequency IDentification uses barcodes to track objects automatically — an early example of the Internet of Things. Now Rexroth is using RFID not only to track locations, but to trigger actions along the assembly line and to trigger reordering of parts at its Industry 4.0 plant in Germany.

Beacon technology responds to physical proximity. At the Rexroth plant, beacon technology is part of worker’s ID badges. When a worker reaches a workstation, the beacon automatically provides information about the language the worker speaks and the degree of detail they’ll need, so the workstation can display the most appropriate information for the worker.

In effect, all the human operators and all the components for the job are tagged in ways that allow the controlling software to “see” all the parts and oversee production as an expert manager would.

The combination of these two technologies allows humans and machinery to work together with the highest level of collaboration, and reduces errors in production significantly.

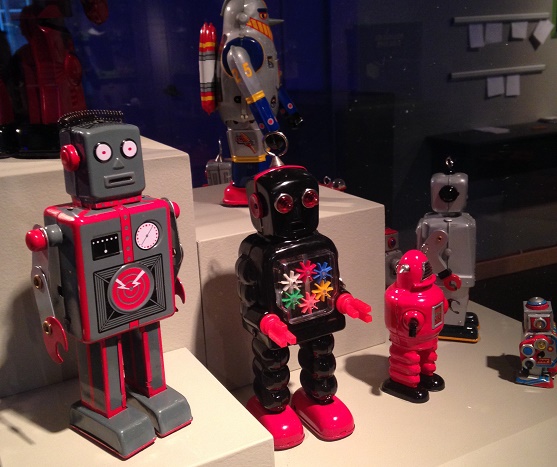

Sure, there may be a slight sense of Robot Overlord, but the improvements in workflow help people get over the feeling quickly.

Rexroth is marketing the system to other manufacturers, and looking forward to the time when communication is not just within the factory. For example, the system now signals people to reorder parts. In the future, it could signal the suppliers of the parts to implement a standing order, bypassing the human workers who might be too busy with other tasks to get the orders in as quickly as they should be.