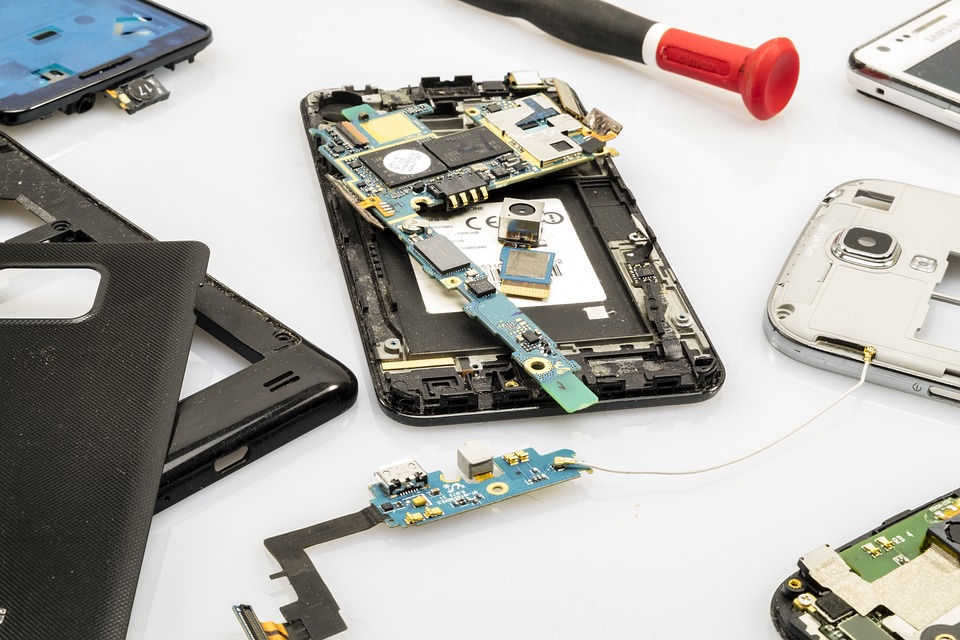

Everything’s humming along, pushing out rows of whatever you make at your facility, and then it’s not. Once you’ve smothered the sparks and quieted the screeching, you have a question to answer: repair or replace? A new study reported in The Guardian says that consumers in general would rather repair machinery than replace it. You… Read more »