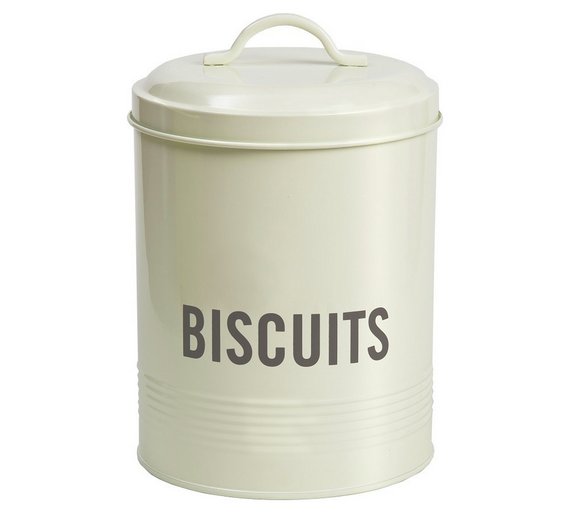

JAXA, Japan’s space program, has landed two robots on the surface of an asteroid. The asteroid, Ryugu, is roughly 200 million miles away. The Guardian described the robots as looking like biscuit tins. For our fellow Americans, we offer this picture of a biscuit tin: Now that you have a clear mental image, you can… Read more »