Safety and productivity are linked in an obvious way in industrial settings: when people get hurt, it slows down and even stops the production process. Clearing the floor, cleaning things up, identifying the problem, instituting new safety procedures or making changes to the machinery — all these steps disrupt production.

There’s another, less obvious link. When machine operators make changes to the machines in order to make the process easier or faster, so they can keep up with production goals, they may be enhancing productivity at the cost of safety.

We hear of workers removing guards, leaving things open that should be closed, even removing parts that seem to be getting in the way of their work. Next thing you know, someone gets burned or cut.

Does sacrificing safety increase throughput?

The workers may feel like they can go faster, but often their adjustments cause trouble with the machinery somewhere down the line. They can’t foresee the consequences of their actions because they don’t know about all the parts of the process. Something that seems to improve their part of the process can have unintended consequences elsewhere in the system.

Pressure to reach unrealistic goals can have all kinds of unintended consequences.

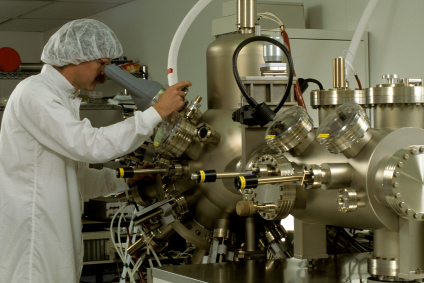

Rexroth builds safety into its machines. Newer components have higher safety standards than legacy components did. It’s still important to follow safety standards — but you should be especially vigilant if you’re using Rexroth legacy units.

We’ll keep your legacy components running perfectly with factory repair and reman. We’re Rexroth electric drive and control specialists. Contact us for any Rexroth electric industrial service and support needs.