New Belgium brewery in Ft. Collins, Colorado, has one of the most efficient, greenest, most sustainable production facilities around. Part of this is using wind, solar, and methane for energy; reusing and repurposing multiple materials for everything from furniture to art installations; reclaiming and reusing water and heat; and thinking from the dumpster back when it comes to recycling.

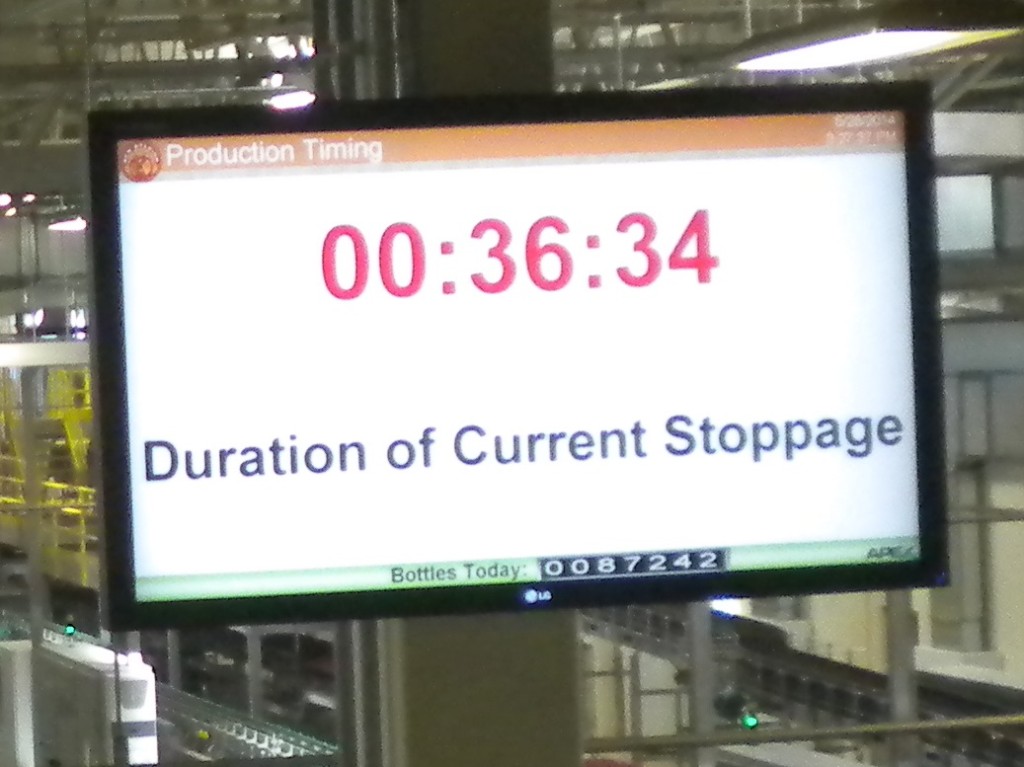

But one of the most important things New Belgum does is to use a high level of very efficient automation in its breweries, and especially in “The Thunderdome,” the packing room. There, New Belgium produces 700 bottles of beer a minute with just 8 to 10 machine operators.

All the operators are engineers, and they use an automatic system to track machine issues so they can easily catch and respond to problems.

New Belgium uses one brand of motion control, but their facility includes components ranging from the oldest that company produces to their newest, cutting edge technologies.

At one point, they considered upgrading throughout the facility. Converting from legacy systems to the newest versions of all the components would have cost millions of dollars. It would also have disrupted production seriously at a plant that runs 24/7 all year.

Besides, it wouldn’t have fit with the culture. New Belgium beer was first brewed in repurposed dairy machinery in the owner’s basement. This is not the kind of outfit that goes in for conspicuous consumption.

Instead, they chose to update controls only, allowing the use of ethernet and some other advantages that made a real difference to the company. The units that were still functioning well and making good beer after all these years?

They didn’t touch them.

That decision saved millions of dollars for the company, without hindering their sustainable systems or their production of world-class beer.

We specialize in legacy Indramat units, but we also work with new Indradrive systems. If that’s what you have in your facility, give us a call. We’ll be happy to help you determine which units need upgrades and which can keep going for a long time to come. We can also help with any needed replacements or repairs.