We’ve written before about the challenges in packaging, but the challenges aren’t all on the production side.

We’ve written before about the challenges in packaging, but the challenges aren’t all on the production side.

Where do consumer package designs come from?

First, from marketing. Manufacturers put extensive thought, research, and effort into determining what shapes, colors, and materials will do the job of getting packages off the shelf and into the shopper’s cart. At that point, no one is thinking about motion control.

A CPG package has to do a lot more than just keep the contents from spilling onto the shelf. It has to be recognizable to a shopper walking past the shelf — in peripheral vision. It has to be identifiable not only as the brand, but also as the item that it is.

It also has to be able, once the shopper starts actually looking at it, to convey the brand identity beyond just saying, “I’m toothpaste, and I’m the same brand you saw on TV.” It has to be able to say, “I’m toothpaste for a fun-loving yet environmentally-conscious young guy like yourself!”

That’s a lot to ask of a package.

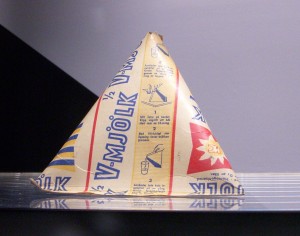

Once the graphic designer gets through with it, it has to go to the packaging designer to make sure that the concept can actually work as a three-dimensional object. There must be some prototyping, and this is often the stage at which the manufacturer says, “Yipes! This is going to cost three times what we budgeted!”

Back to the drawing board.

Only then do the engineers get involved. Figuring out how to adapt the concept to a standard production model is often the way to get costs back down to profitability. This is also usually the point at which someone has to think about packing the truck or shipping container with the packages, ensuring that the transport can be packed efficiently and that the packaging doesn’t limit fuel efficiency.

And then the factory has the challenge of streamlining the process and making it work.

Motion control makes it possible to get an accurate print and cut, and then to take that two dimensional object and fold, roll, crimp, or glue it into a three dimensional shape. Motion control is essential for getting the product into the package or the package outside of the product. And motion control is usually involved in getting the packaged product into a box, case, or pallet so it can head out to the retailer.

Servo motors make it easier and more practical to produce packaging, but they’re at the end of the process. If something goes wrong at that point, it’s not a matter of giving the designer another couple of days to work on it.

We know that your work is very important. If your Indramat comp0nents need service, we take it as seriously as you do. Call us immediately when you need Indramat support — and put our number in your phone right now, just in case.