One of the things that smart machines can do is gather data. Sensors are proliferating, and information is being gathered. So what will we do with that information?

Rexroth’s Dr. Steffen Haack believes that industrial motion technology can use the same kind of algorithms that let Netflix offer you tempting movies or Google find the answer to your question.

“With machine learning,” he recently wrote, “software can detect wear patterns and its effects on manufacturing systems… Numerous sensors in and on all critical components and modules continuously record operating data. This data is sent to a cloud where status information is calculated, drawing on data from all connected systems. With every data set, the software is better able to recognize patterns and the prediction accuracy for wear and potential failure increases continuously.”

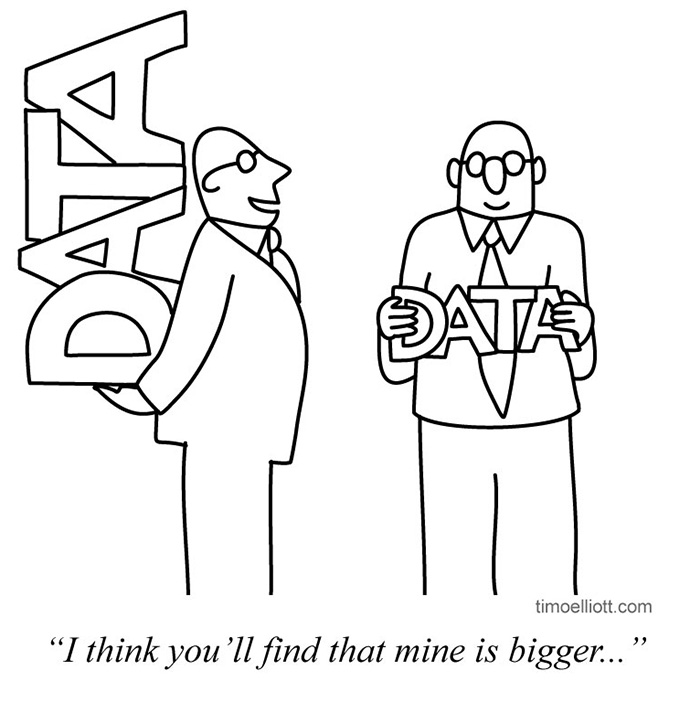

And that’s just a starting point. One of the interesting things about big data is that additional data shows relationships and patterns that can’t be predicted with smaller data sets. Since collecting the information is not the hard part of the job, it makes sense to collect data that doesn’t answer current questions. Chances are, that information will answer future questions that we can’t currently predict.

“The principle is self-evident,” Haack wrote. “The more comprehensive the data set, the greater the potential use for all involved.”

While the principle might be self-evident, it can be hard to get decision makers on board with the idea that their data will help someone else and may help their own factory further down the line, just as everyone else’s data can help them.

That may not translate in their minds to sufficient ROI. It may make them think of security breaches, not of one-world harmony propelling all of us into the future.

That’s fine. There’s a place for early adopters in this world, and a place for companies that want to keep their current machines running as long as possible. We’re experts in Rexroth’s legacy machines. We’ll help you keep them in trim while you wait to see what Industry 4.0 looks like when it’s ready for general use.