Rexroth servo motors can be used in really creative ways to get jobs done. If you’ve made some creative changes in your industrial motion control system, though, it could mean that the axis of rotation on your Rexroth servo motor isn’t lined up with the center of mass. As your manufacturing processes change slightly over time, you might find that your servo can’t maintain the loads it needs to anymore and is experiencing a higher rate of failure. So how do you solve this problem?

You can do calculations about load for off-center machines through specialized software, but that requires an investment. Doing a manual calculation out is a much more cost effective way, although it isn’t easier. An article from Control Engineering has a great explanation of how to calculate out inertia in off-center style machines. But how do you solve this problem when you don’t know all the measurements?

The servos at your facility may have been installed long ago by someone else… possibly well before you were born. Where should you look to find the data you need for your calculation? Start with a manual request. Make sure you know the model number of the Rexroth servo motor you’re looking for — and make sure that it’s an electric servo. Send in your request and we’ll deliver the manual to you.

With the needed data and some basic understanding of physics, you can determine the inertia ratios involved and make sure that you aren’t asking too much of your servo.

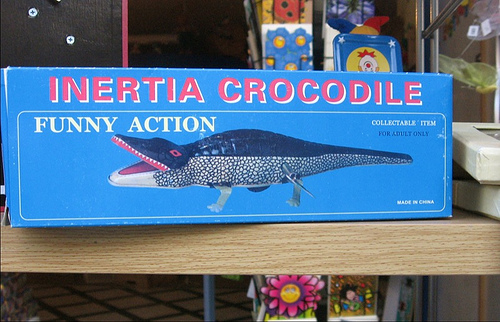

Doing this calculation out can help you get a better idea on just how much your machine can take and if there are issues with the servo motor itself. If the number you find for the mass of your tool seems far to heavy or way too light, it means that the servo isn’t functioning at its full potential. An easier way to do all this (and not be eaten by the Inertia Croc) is to just give us a call.