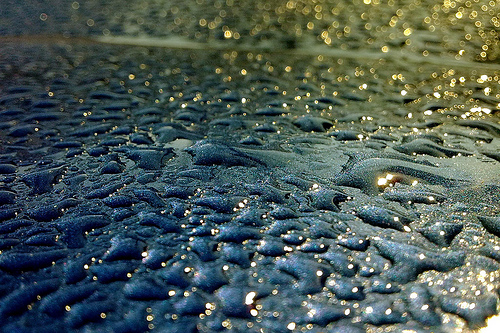

If your facility is in a warm, humid climate, when your servo is stopped you might run into issues with condensation. Condensation is about droplets of water forming on your servos when the temperature is close to the dew point. Dry environments like Arizona or Utah have dew points as low as freezing temperatures during even the hottest of months whereas in areas like Louisiana or Florida, dew points can be just a few degrees below the air temperature.

While servo drives are (or at least should be) protected inside of cabinets that are closely monitored for temperature, motors can prove more complex since they’re usually out in the environment instead of in a controlled area. When servo motors are off, however, you can encounter some big problems if they’re in really humid conditions. This can lead to electrical shorts and even rust, causing damage to the motor. If your plant shuts down for a week of scheduled downtime, you can come back to servo drives ruined by moisture. How do you solve this issue?

Solutions

The first solution is to avoid creating the conditions that lead to condensation. There are several options here.

Reduce humidity. If possible, try to store the servo motors in a low-humidity environment. This can be achieved with a dehumidifier or by using desiccants (moisture-absorbing packets) placed near the motors.

Gradual cooling can also reduce the dangers. When turning off the motors, allow them to cool down gradually. Avoid sudden temperature changes by leaving them powered on at a low voltage for a short period before complete shut down.

In very humid environments, consider storing the motors in a temperature-controlled cabinet with slight heating. This can help maintain a constant temperature and prevent condensation.

There are other steps you can take to help protect your motors.

You can also apply a thin layer of moisture-resistant lubricant or conformal coating to the motor housing. This can help repel moisture and prevent condensation from forming on the surface.

If the servo motor has any vents or openings in the housing, consider temporarily sealing them with tape during storage to minimize moisture ingress. Remember to remove the tape before powering on the motor again.

When storing the motors, try to position them vertically with the shaft pointing upwards. This can help any condensation that forms to drain away from sensitive components.

By following these tips, you can help prevent condensation from damaging your servo motors during storage or downtime. Remember, the best approach might depend on the specific humidity level and storage duration in your situation.