Manufacturing accounts for one quarter of all workplace injuries in the United States. That’s about 2.9 million injuries a year. Fortunately, automation can increase safety while lowering costs.

Give the robots the dangerous jobs

One of the reasons for industrial automation is to take human beings out of dangerous work environments. There’s no reason to put human workers into harsh environments when robots can do the tasks instead.

This makes sense even when the machinery is creating the dangers in the work environment. As machines become more automated and the human activity around the machines consists more of monitoring than hands-on work in tandem with the machines, human workers face fewer dangers.

Avoid repetitive motions

Packing products or filling pallets may not seem like dangerous jobs. But human beings are not designed to repeat the same motion over and over. When we’re forced to do so, we tend to get hurt. Repetitive stress injuries keep workers off work for longer periods than falls, vehicle accidents, fires and explosions.

Robots, on the other hand, thrive on repetitive motions. Doing the identical thing over and over and over with identical results every time is a machine’s favorite task.

Be safe with robots

Since 1984, OSHA has recorded 40 robot-related injuries. Nearly all were cases of crushing, usually when people were in a robot’s space without taking the required precautions. Most injuries were caused by unexpected movements. One was a worker who had a heart attack when trying to do a job usually done by a robot; that doesn’t seem to be the robot’s fault. Indeed, when human workers climb over fences and crawl through barriers to get into the robot’s space, they are clearly courting danger. Being crushed by a robot is a terrible way to die.

Collaborative robots with sensors that cause the robots to stop when they sense the presence of humans are the best solution to this problem. However, standard safety measures are usually enough when they are followed correctly. And in fact, only 27 of the 4,585 industrial fatalities of the past 25 years have involved robots. Make sure to follow all safety regulations.

Speaking of safety, have you looked at your Rexroth drive and control system manuals recently? You might not even know the safety procedures you should be taking. Request a manual for your machinery and make sure you know the dangers.

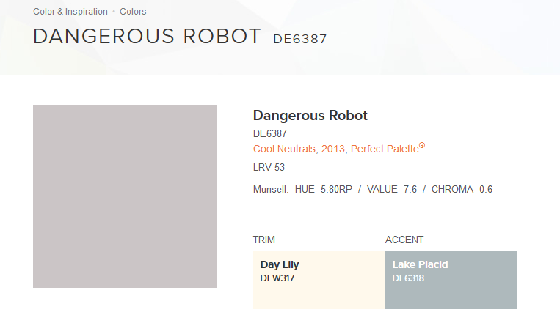

Fortunately, automation reduces human errors and increases safety most of the time. As safety systems continue to improve, “Dangerous Robot” may mean nothing more than the color shown on the paint chip at the top of this post.