One thing you might think industrial automation would not have to worry about: cross-cultural communication. With Rexroth’s open source language available, all machinery can communicate freely and the Industrial Internet of Things is up and running.

Think again.

“In Germany it’s very systematic and process driven,” a Rexroth spokesman said at the Smart Factory Industry Forum in Chicago. The Rexroth Industry 4.0 facility in Germany is certainly an excellent proof of concept, he explained, but the same system might not work in the United States.

On the other hand, he pointed out, the American approach can get products to market faster, and that’s key to modern industrial success.

The Forum found agreement that global standards are needed — and not just a global agreement on which programming languages to use. Programming standards may be the easiest win. Global standards on safety and security may be the tougher project.

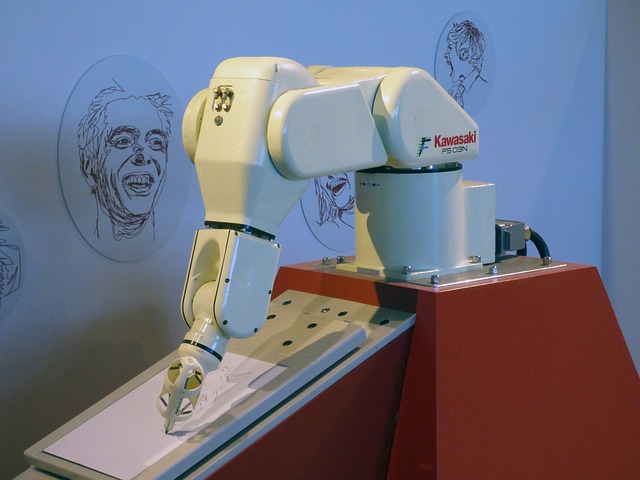

The International Labor Organization has set standards for worker safety in agriculture, mining, construction, and more. There is even a specific document on working with machinery, created in 2013. This Code of Practice deals with chainsaws and earth-moving machinery, though, not with human-collaborative robots. And the United States doesn’t always follow ILO agreements, in any case.

Security systems are much less mature than safety systems, and the security systems of one facility are often intentionally separate and incompatible with security systems of another. But there is a growing awareness that security and safety are intertwined in the IIoT. Working on one without the other could lead to unintended consequences which could threaten human safety.

The IIoT is also data-based, and workers’ ability to use relevant data may vary from one region to another. Companies’ willingness to trust workers with data may also be a factor that differs in different regions.

While the details are still in discussion, it’s clear that the rise of Industry 4.0 will require more than the technical ability to get machinery networked and in communication with other machinery. There will also be a greater need for human communication and consensus.