Nanotechnology is one of the most promising fields of manufacturing, when it comes to innovation. Solar power cheaper than fossil fuels coming right up! And semiconductor chips are right up there, too.

But when you’re building something really small, a few particles of metal cause as much trouble as golf balls in the production line would cause for packaging lines. Particle contamination is a huge problem for tiny components.

These particles, according to Rexroth’s Paul Streatfield, are caused by metal-to-metal contact along a conveyor belt or similar system. Sometimes manufacturers try to solve the problem by putting the tiny products into a vacuum chamber to prevent airborne contaminants.

“The problem with this method,” says Streatfield, “is that the bearings are also inside the vacuum.” Particle contamination, in this case, is actually created within the vacuum chamber.

A better solution is just to get the good up off the conveyor belt.

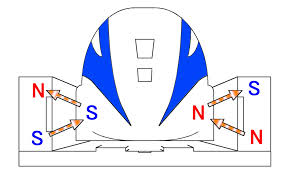

Remember playing with magnets as a kid, making a stack of magnetic rings levitate? If not, just think about levitating trains.

The same concept can work in a factory or lab setting to keep the objects away from the metal particles. The Bosch Rexroth LeviMotion system provides contactless transportation, solving the problem of particle contamination from metal-to-metal contact in the transport system itself.

Simple, smart, and elegant solutions are what Rexroth is all about. That’s why legacy systems as well as newer components work beautifully for far longer than you’d expect. If you need support with your Rexroth systems, give us a call. We specialize in legacy systems, but we’re also ready to provide the support you need for new Rexroth electric systems.