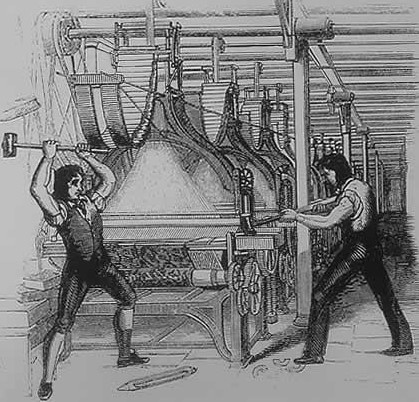

Change can be tough, whether it’s running out of your favorite coffee and having to drink something else or seeing massive changes in technology completely change your workflow. The artisans who were put out of work by the new-fangled inventions of stocking frames and power looms in the early 1800s were the original Luddites.They crept into the new factories and broke the new machinery, both from fear about their jobs and also from hatred of the new machines.

The term “luddite” is used today to describe someone who is afraid of or disapproves of new technology.

Origin of the term “luddite”

Ned Ludd was a weaver who supposedly broke a couple of stocking frames in 1779. The stocking frame was a partially automated knitting machine invented during the reign of Queen Elizabeth I of England. Its inventor showed it to the queen, but she worried that it would be bad for the English knitting industry and wouldn’t support it.

By 1800, the stocking frame had evolved from a machine that manipulated yarn laid into it by human workers to knit flat pieces of heavy fabric into a sophisticated machine that could knit lace. A couple of decades later, stocking frames and mechanical looms were indeed taking jobs away from human artisans.

The owners of the machinery were the ones who benefited from it financially. Consumers were able to buy cheaper, machine-made goods. The knitters and weavers who had spent their lives developing skills were the ones who suffered as their abilities became less valuable and jobs for them became scarce.

Workers’ rights or technophobia?

Craftsmen who protested against the loss of rights that went with the industrialization fo the fiber industry were called Luddites after Ned Ludd, who had by this time become a legendary figure like Robin Hood. It wasn’t that they objected to the development of stocking frames into better stocking frames. They objected to the hardships faced by workers whose only choice for employment was tending the machines.

Now we use the term to talk about people who resist new technology, not people who agitate for workers’ rights.

But there are good reasons for choosing to stick with legacy machinery. Cost is an obvious one. Retrofitting your current Rexroth machinery is going to be much less costly than buying all new units.

You may also find that updating to new motion control systems will require much more than just replacing a few pieces of machinery. Differences in size and set up can mean rearranging and reorganizing your entire plant, at massive cost and inconvenience.

Often, a remanufactured unit, complete with factory warranty, is a better choice.

Businesses are always looking to save on costs and generate higher profit margins – that notion even predates the power loom. You’re not a luddite if you see ways to keep using your current machinery in cost effective ways. We can help you do that. Call today for insights into your current Rexroth electric motion control system and how best to make the changes you need.