New connections in factories are opening lots of possibilities for increasing performance, tracking environmental factors, and heading problems off at the pass. Sensors catch temperature, vibration, pressure, velocity, and all the myriad variations in the performance of machines.

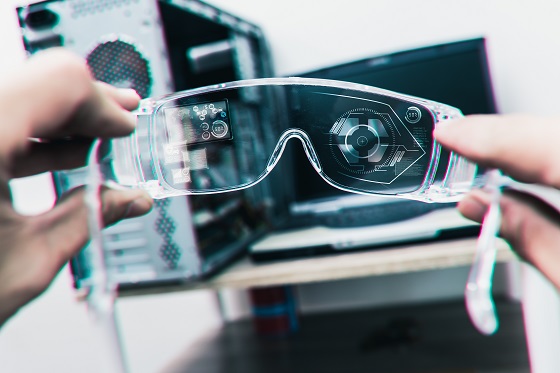

But they can also track human performance. Smart wearables can identify the highs and lows in a factory worker’s day and trigger “learning events” to help improve routines.

For example, a worker might tend to slow down in step three of a work process. A smart wearable can catch this pattern and offer the worker a refresher lesson on step three in the worker’s native language.

Wearables can also alert workers to environmental dangers, such as hot surfaces or spilled liquids. Managers can send messages to workers wherever they are — and that could include the worker who is about to step in front of a fork lift.

The same type of wearable that tells consumers how many steps they take in a day and how well they sleep can report wellness data from factory workers. If temperatures are too high, pulse rates are out of line, or proximity to equipment is too close, the worker can receive a warning message.

So can the supervisor. For some people, this is nerve wracking. While they might appreciate hearing an alarm if they’re too close to a machine for safety, most workers don’t enjoy the feeling of being monitored by the boss all day.

Still, plenty of consumers share their daily steps with friends, getting the benefit of accountability… or forgetting all about it over time.

Those who use wearables for these purposes agree that establishing trust and getting input and buy-in from everyone can be the key to success.

Data can also be collected anonymously. Tracking levels of fatigue or stress in the factory as a whole can be just as valuable as singling out an individual whose eyes keep closing. Elevated stress levels showing up at a particular time of day or even in a seasonal pattern can lead to observation and change, resulting in safer, more productive conditions for everyone.

In the meantime, you can count on us any time you need Rexroth electric motion control support. We offer phone and field support, factory repair and reman, and troubleshooting for Rexroth drives, controls, and servos, including legacy units. Call 479-422-0390 for immediate assistance.