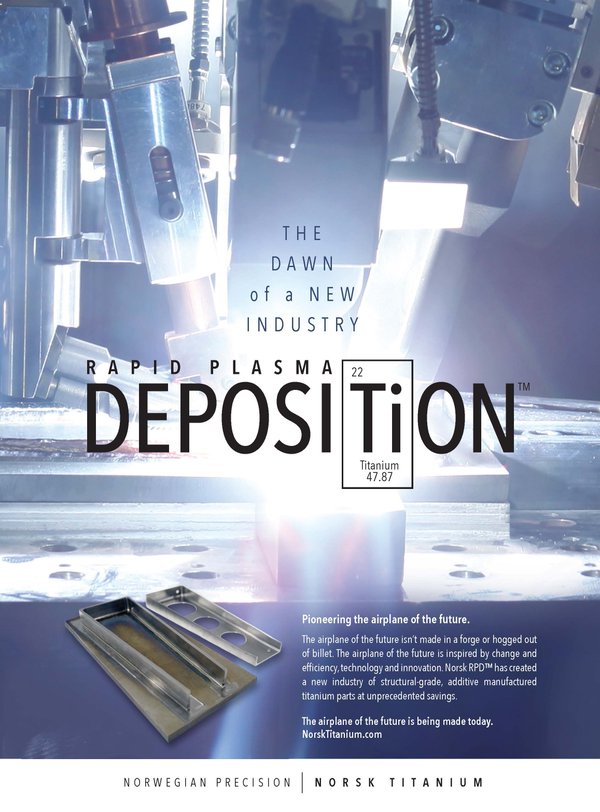

The world’s first industrial-level 3D printing facility will be built in the U.S. in partnership between Rexroth and Norsk Titanium, a major aerospace tech company that uses additive manufacturing in titanium to make specialized parts — check out their ad above.

10 servo axes will control the feeding of the titanium wire into the build table, the motion of plasma arc torches, and other aspects of the process.

This new technology is designed to replace old-school forge methods with cleaner, more precise manufacturing processes that better meet the needs of the high-tech aerospace industry.

If you’ve spent much time in those old-school forge processes you know that this is a punishing type of work. Moving to additive manufacturing instead will be a humane change. It can also save as much as half the cost of parts compared with forged parts.

Norsk has developed two new 3D printing technologies specifically to create airplane parts, and they’ve reached the high level of Technology Readiness Level Eight (TRL 8) in tests coordinated through the Federal Aviation Administration. TRL 8 is the highest level of certification during testing before airplane parts can actually be used in missions. These parts are concerned flight ready, and will be designated TRL 9 after they’ve successfully been used in regular (not test) flights.

Norsk can now ship parts for defense and aerospace applications, and they expect to be delivering parts to commercial airlines this year.

They chose Rexroth technology because of the robust software as well as the precision, accuracy, and stability of Rexroth motion control. There’s no question that Rexroth motion control continues to be key to the newest technologies.

If you’re using Rexroth motion control, you know why Norsk chose Rexroth. Are you in need of support? We provide fast, friendly, expert support with both legacy Rexroth Indramat motion control and the latest IndraDrive electric motion control systems.