Rexroth has a long history of focusing on training. From its apprenticeship programs to online training options, Rexroth is an industry leader in this area. And now there is a new tool in the Rexroth Training kit.

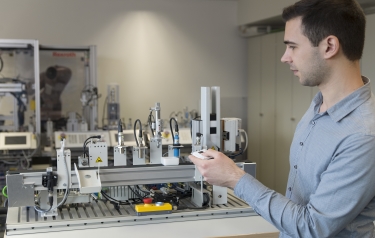

Cyber Physical System (CPS) i4.0 uses new hardware and software in a networkable cube assembly system. The cubes in question are small cubes, about the size of a Lego block. The training system includes a workbench with up to 12 sensors and all the components needed to transport the cubes along a conveyor belt. The machinery identifies the cubes and collects information. Operators oversee the process, store and transmit the data, and upload data with standard browsers.

Users can learn to program movement sequences in standard languages. This continues Rexroth’s efforts to work with the language people in the workforce already know. These art typically C++ and other languages in that family. Often, proprietary machinery requires training in new machine languages. This can make for a steep learning curve for software. If you have to hire people who know the specific languages, or train current personnel, you may face real obstacles to using new technologies.

With the new training system and Rexroth’s Open Core system, less training is required — and it doesn’t require human trainers.

The system also demonstrates component-led production. This involves marking workpieces with RFID that tells machines what to do next. Instead of programming machines to perform specific tasks and working to get the right components to the right machines in the right position, machines can take instructions directly from the workpiece. This option makes machinery much more versatile, and accommodates increasing consumer demand for individualization of products.

The training system also teaches people how to connect production data with ERP (enterprise resource planning ) and MES (manufacturing execution systems) software. Getting the data that machines collect to the systems that analyze that data and provide actionable information is an essential step toward Industry 4.0.

Since the hardware and software are identical to the tools used in actual working facilities, the training is directly applicable to life size factories.