In 1911, a machine was patented that could feed sheet metal through a pair of polishing rolls and spiff up the metal just as nicely as if a human being spent hours polishing it. The trick was to send one of the rolls in one direction and the other roll in the opposite direction, at the same time.

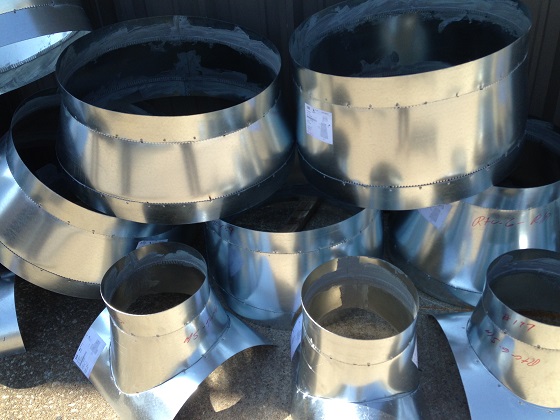

Modern sheet metal fabrication is a little fancier, but not much. The machines will destack or decoil metal sheets, align, and feed the press and many of them are built to do little jobs to prevent common problems, like straightening edges of the sheets of metal or making certain that only one sheet at a time is fed through the machine. Transfer of the finished sheets or blanks to another machine for final formation is now often automatic, too, even when the final finishing may still be done by craftsmen.

All the tasks involved in sheet metal fabrication require servo motors. A brushless AC servo motor, the type pioneered by Indramat, now Bosch Rexroth, back in the 1970s, is the servo of choice.

Rexroth legacy motion control systems are often found in printing presses, too, but the consequences of a lack of precision when feeding sheets of paper through a press are different from the consequences when you’re feeding metal through a press. Imprecision in either situation can mean a waste of time and money, and we don’t mean to downplay the importance of that, but a crumpled sheet of paper or a misaligned image poses little threat to life or limb.

It makes sense that contact-less feeders are usually preferred. And that means that the high level of precision offered by a servo motor is a necessity. Rexroth’s legacy CLM controls are still working well with sheet metal feeder machines across the nation and around the world.