Automation is increasing in the United States and across the globe. Industrial automation is naturally being extended by improvements in technology. New sensors and more efficient programming increase the range of tasks that can be automated, and servo motors make ideas into reality, as they’ve been doing for more than a century.

Many observers fear that complete automation in factories is the next logical step. Factories have already gone from employing hundreds of semi-skilled workers to having smaller footprints and staffs composed of just a handful of engineers.

Toyota isn’t following this lead. Their internal research has found that human workers still put cars together better and faster than robots. “Machines are good for repetitive things,” Fast Company quoted Toyota’s Wil James as saying, “but they can’t improve their own efficiency or the quality of their work. Only people can.”

The focus is therefore not on reducing labor costs or even on making people more efficient. Rather, automation — as well as changes in materials, workflows, and machinery — is designed to help and support the human workers.

The human workers, meanwhile, are encouraged to identify opportunities to shave seconds off of tasks. They may see how a swivel chair would be faster than stepping back and forth from one spot to another. Or think about how a conveyor belt, with people standing and waiting for the next workpiece to reach them, could be replaced by robots moving each piece into place at just the right moment.

By thinking of robots as helpers, Toyota has been able to keep people doing the creative, skilled work at which they excel. By contrast, other manufacturers sometimes think in terms of how a robot can take over a task. Attempts to figure out how to make a robot load a pallet or plant crops, rather than examining the human work for opportunities to make it easier and faster, can end up with a mediocre replacement for a human worker.

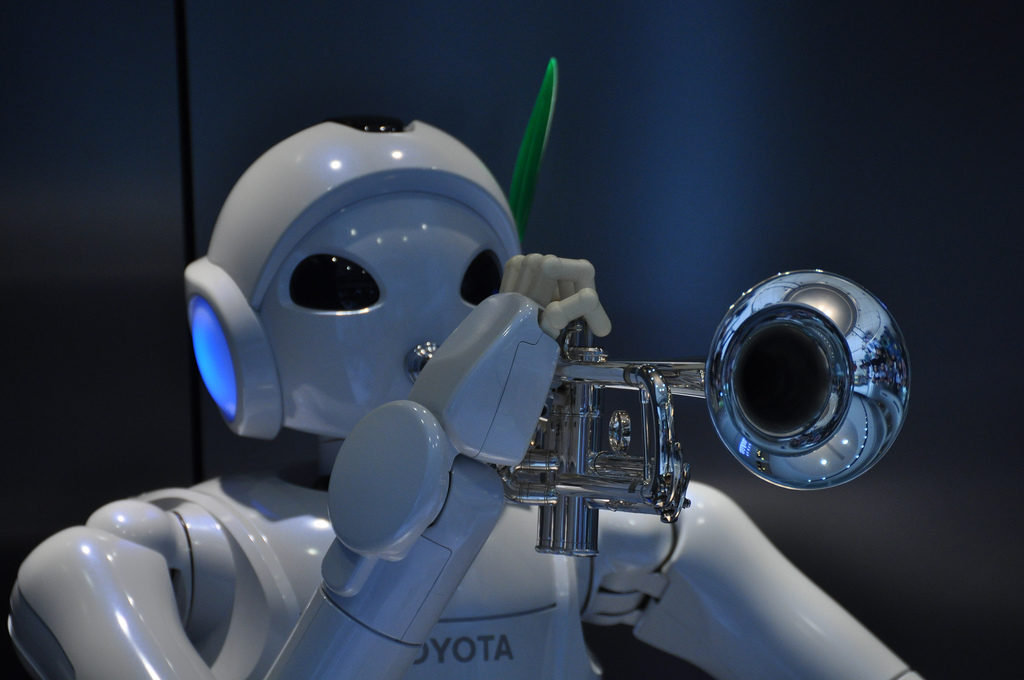

Toyota’s Partner Robot shows the attitude in a dramatic way.

No matter how you choose to make a robot move, a motion control system will be required. We specialize in Rexroth electric motion control machinery. We offer phone support, field support, and factory repair.