A study by Frost and Sullivan found that both servo motors and stepper motors will be in increasingly high demand in the near future, with the global rise of industrial automation and increasing demand in the areas of packaging and automobiles.

Servo motors and stepper motors are often thought of and spoken of together in this way.

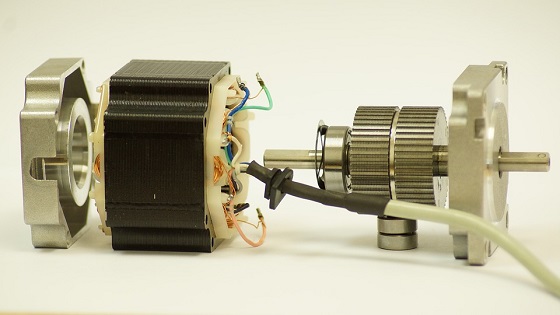

Stepper motors have electromagnetic coils that lay out a phase pattern that defines their movements. As the coils are turned off and on, the changes in the magnetic patterns cause the motor to move step by step. Since the pattern is predefined, you know where in the process the stepper is as long as you know which step in the pattern it’s on. Steppers can have feedback systems, but often they run in an open-loop system.

Servo motors have encoders keeping track of where they are. They respond to feedback within the system to keep the motor running at the right speed for the work it’s doing. By definition, a servo uses a closed-loop feedback system.

In situations where you can choose between the two, steppers are often cheaper than servos. However, they don’t work as well at either fast or slow speeds — they’re really best for steady, middle range speeds. They’re less efficient than a servo, too. Both types can be equally accurate, especially in lighter applications.

Some say that servo motors require more upkeep, but brushless servos like those from Rexroth require very little maintenance. In fact, we see quite a few from the 20th century that have never needed any upkeep before. When your servo does need repair, it’s usually simplest to replace it and return the old motor to the factory for repair. This keeps your downtime to a minimum.

Call us at (479) 422-0390 for repair and support for any Rexroth electric industrial motor, drive, or control.