OSHA has updated the Industrial Robot Systems and Industrial Robot System Safety manual, in cooperation with the Association for Advancing Automation.

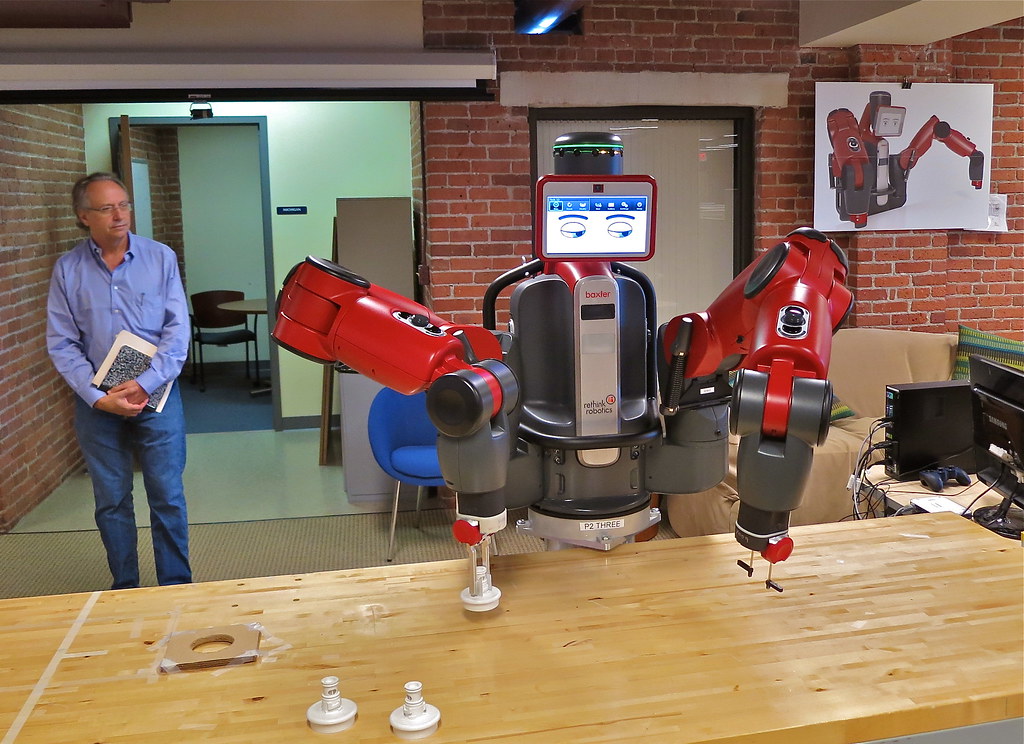

One motivation for the update was simply the increasing use of robots in workplaces. 2021 was a banner year for robot adoption, and more workers than ever are now working alongside robots. The increasing use of collaborative robots, robots which work directly with human workers, has also changed the safety issues which come up in the use of robots.

Errors leading to risks

The OSHA manual identifies several possible causes of danger from robots:

- Human error in programming or integration

- Control errors, such as software glitches or radio frequency interference

- Unauthorized access

- Mechanical errors

- Time pressure, which can cause people to skip safety measures

- Environmental sources such as exposure to heat or water can lead to errors

- Power failures

- Improper assembly or installation

The manual goes on to outline specific safety measures and procedures required for safe use of robots. For example, this statement covers training needs: “Workers who assemble, install, program, integrate, operate, maintain, or repair robots, robot systems, or robot applications should receive adequate safety training, and they should be able to demonstrate their competency to perform their jobs safely.”

Robot dangers and safety measures

Rexroth has implemented safety measures in its drive and control systems. These efforts have become more robust over time. Recognizing that some 89% of workers ignore safety rules, safety procedures have gradually been automated so that it is more difficult for workers to bypass them.

For example, robots may be equipped with sensors that let them know when they make contact with something soft and squishy (like a human) and programming that will instantly stop their movement in case of such a contact.

If you use legacy components, however, your machinery may not have all those safety measures in place. In that case, it’s up to the human beings to be careful around the robots — or it’s up to you to make sure that your workers are physically separated from the robots.

Making sure that your machinery is in peak condition is an important part of robot safety. Seeing a Rexroth error code and immediately clearing it and restarting without figuring out the problem and solving it — that’s often a dangerous choice.

Instead, call us for immediate assistance whenever you need service or support for your Rexroth drive and control systems.